Over 40 years of experience

We are an ENERPAC specialist and local supplier for Lincoln Lubrication systems, pneumatic, fittings and industrial supplies.

Equipment Service, hydraulic repairs, tool hire

Featured products

-

EP3204JE-G, Electric Hydraulic Pump, 3,0 liters Usable Oil, Schuko CEE 7/7 Plug, with Gauge

Regular price $10,000.00 AUDRegular priceUnit price / per -

EP3304SE-G, Electric Hydraulic Pump, 3,0 liters Usable Oil, Schuko CEE 7/7 Plug, with Gauge

Regular price $15,000.00 AUDRegular priceUnit price / per -

P39, Single Speed, ULTIMA Steel Hydraulic Hand Pump, 672 cm3 Usable Oil

Regular price $865.10 AUDRegular priceUnit price / per

Enerpac

EP3204JE-G, Electric Hydraulic Pump, 3,0 liters Usable Oil, Schuko CEE 7/7 Plug, with Gauge

Share

Enerpac Upgrade Program

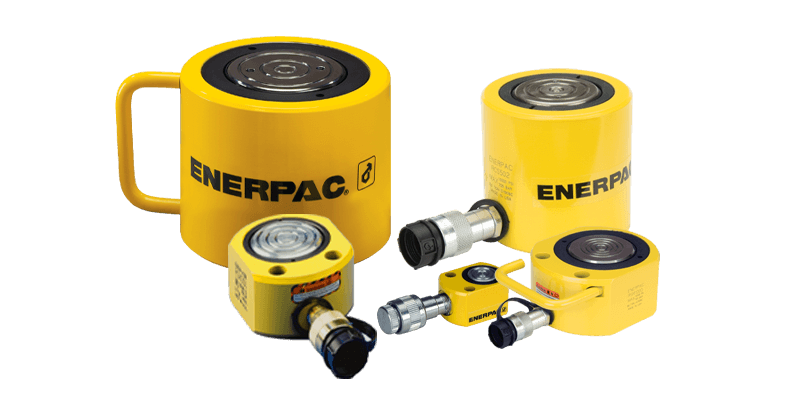

General Purpose Cylinders

- Upgrade general purpose RC Series Cylinder

- Upgrade to the new RC Trio!

- Save 30%

FAQ

What hydraulic pump do I need for my application?

Hydraulic gear pump selection depends on the number of factors such as: required oil flow rate, desired working pressure of the application, hydraulic cylinder oil volume displacement, speed of the hydraulic motor and desired torque of the pump. We strongly advise to collect all the data explained above prior to the gear pump purchase.

How many types of hydraulic cylinders are there?

The three most common hydraulic cylinder configurations are piston hydraulic cylinders, telescopic hydraulic cylinders and plunger hydraulic cylinders

What is the difference between double and single acting hydraulic cylinders?

- Double-Acting (D/A) – have a port for each side, supplied with hydraulic fluid for both, the retraction and extension. Used for power up – power down applications.

- Single-Acting (S/A) – hydraulic fluid enters through a port on one end of the cylinder, which extends the rod by means of area difference. An external force or gravity returns the piston rod inside.

What are the common causes of hydraulic cylinder failure?

- Side loading

- Contaminated Fluid

- Rough or scored rod

- Aggressive Environment

- Dieseling effect

WHAT OUR CUSTOMERS ARE SAYING

"Extensive range of Hydraulic components, have had cylinders refurbished and purchased new Enerpac cylinders here. Plenty of visitors parking available and prompt response to my enquiries."

Chris, Melbourne

About Us

Founded in 1973 and based in Melbourne since 1987, AD Automation are Enerpac specialists and local suppliers of SKF Lincoln lubrication systems, pneumatics, and industrial supplies, serving industries including aerospace, mining, rail, and food and beverage.